Industrial pure water equipment

Stable Quality | High Efficiency | Customized Industrial Solution

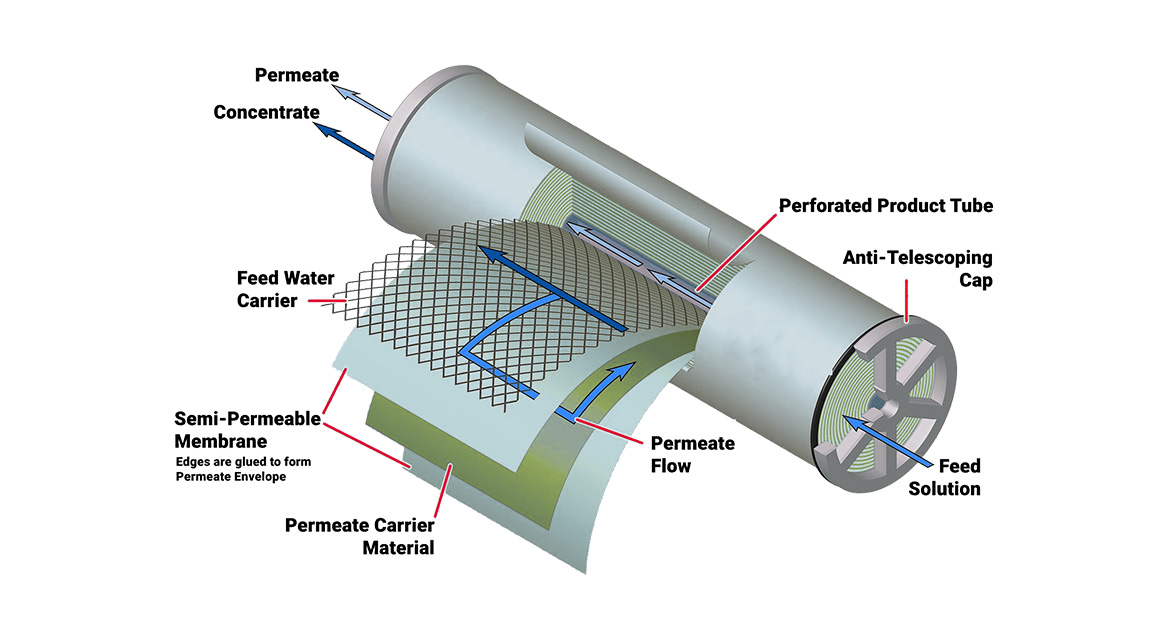

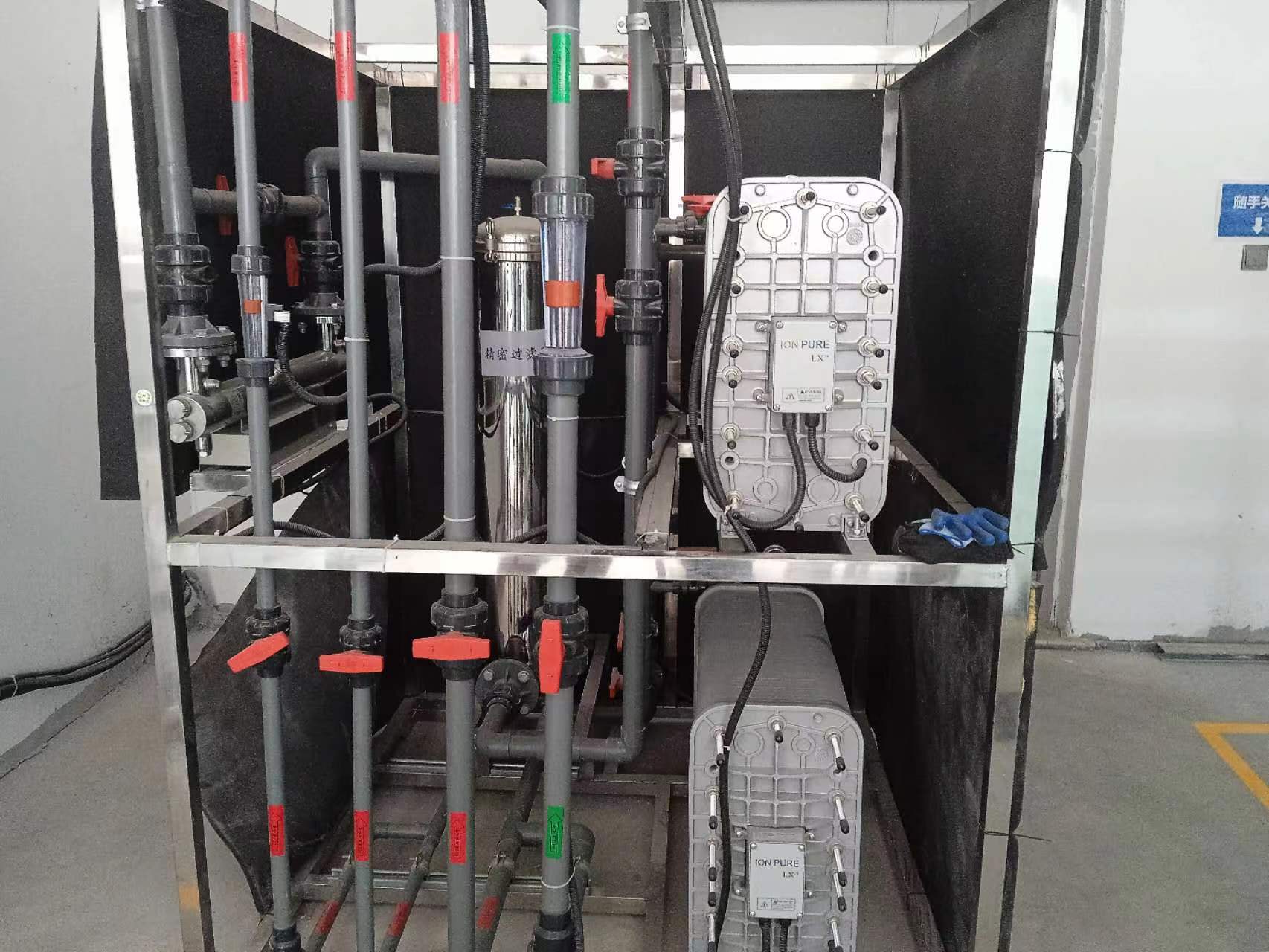

Industrial Pure Water Equipment is designed to produce high-quality purified water for industrial applications. The system typically adopts pretreatment + reverse osmosis (RO) or RO + EDI technology to effectively remove suspended solids, dissolved salts, heavy metals, organic matter, and microorganisms, ensuring stable and reliable pure water output.

This equipment is suitable for long-term continuous operation and can be customized according to raw water quality and industry-specific water standards.

Typical Process Flow

Raw Water

→ Pretreatment (Sand Filter + Carbon Filter + Softener)

→ RO System (Single Pass / Double Pass)

→ (Optional) EDI System

→ Pure Water Storage & Distribution

Key Advantages

-

Stable pure water quality for industrial use

-

High desalination efficiency and low conductivity

-

Automatic operation with PLC control (optional)

-

Low operating and maintenance cost

-

Modular, skid-mounted or containerized design

-

Customizable capacity and configuration

Technical Specifications (Reference)

-

Capacity: 0.5–100+ m³/h

-

RO type: Single-stage / Double-stage

-

Product water conductivity:

-

RO: ≤5–10 μS/cm

-

RO + EDI: ≤0.1 μS/cm

-

-

Recovery rate: 50–75%

-

Material: FRP / Carbon Steel / Stainless Steel

Applicable Water Sources

-

Tap water

-

Groundwater

-

River and lake water

-

Industrial process water

Application Industries

-

Manufacturing and industrial process water

-

Boiler feed water

-

Food & beverage production

-

Pharmaceutical and medical industry

-

Electronics and semiconductor industry

-

Chemical and power plants

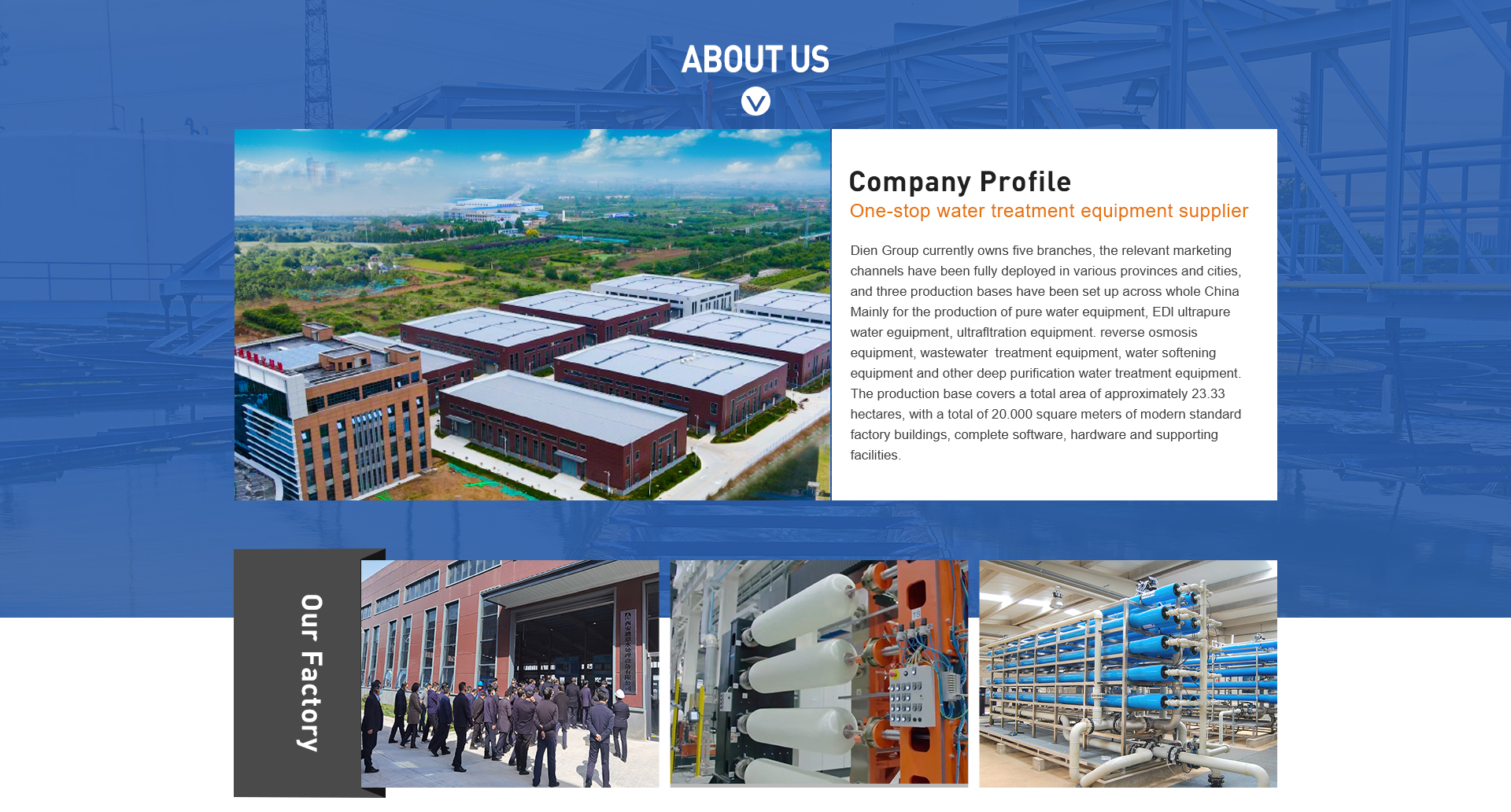

Why Choose Us

-

10+ years experience in water treatment manufacturing

-

One-stop industrial pure water solution provider

-

OEM & ODM service available

-

CE / ISO standard components

-

Professional design, installation, and after-sales support