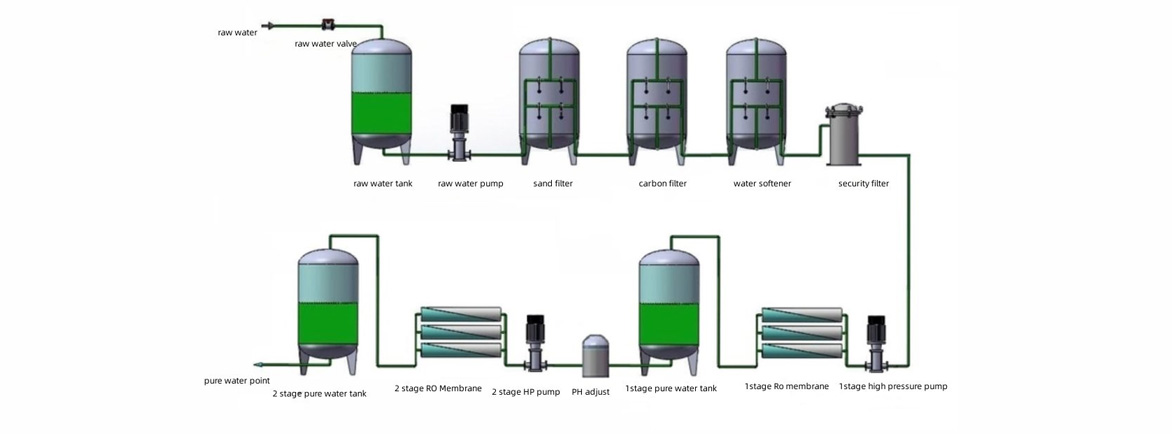

7T/H pre-treatment equipment

The 7T/H Pre-Treatment Equipment is designed for industrial water filtration before reverse osmosis systems. With a treatment capacity of 7 tons per hour, it effectively removes suspended solids, turbidity, residual chlorine, organic matter, and large particles, ensuring stable inlet water quality and extending the service life of RO membranes.

This pretreatment system is widely used in industrial pure water projects, manufacturing plants, food & beverage factories, and boiler feed water systems. The configuration can be customized according to raw water quality.

Key Features

1、Durability: The main body is constructed of 304/316L stainless steel, offering excellent corrosion resistance. It can withstand water environments with an acid or alkali concentration of ≤10%. This extends its service life by 5-8 years compared to standard carbon steel or plastic water treatment equipment, reducing equipment replacement frequency and maintenance costs.

2、Stable and controllable water quality: Equipped with an intelligent water quality monitoring and automatic adjustment system, it monitors key indicators such as effluent turbidity, hardness, and microbial content in real time. When water quality fluctuates, it automatically adjusts the filtration accuracy or disinfection dosage to ensure that the effluent water quality compliance rate remains stable at above 99%.

3、Easy to clean and maintain: The internal flow channel of the equipment is designed to be smooth without dead corners, and supports online backwashing function, so the filter element can be cleaned without disassembly; the surface of the stainless steel shell is smooth and easy to wipe, and it is not easy to adhere to dirt. Daily maintenance only requires regular inspection of valves and instruments, which is easy to operate.

4、Safe and environmentally friendly: Stainless steel releases no toxic or hazardous substances, complies with food hygiene standards (such as GB 4806.9), and is suitable for drinking water and food processing water treatment. Some equipment supports water resource recycling design, reducing wastewater discharge by over 30%, in line with green production needs.

Technical Parameters (Reference)

-

Flow rate: 7 T/H

-

Filter vessel material: FRP / Carbon Steel / Stainless Steel

-

Filter media: Quartz sand, activated carbon

-

Control mode: Manual / Automatic (multi-port valve or PLC)

-

Working pressure: 0.1–0.6 MPa

-

Backwash mode: Automatic or manual

- Suitable Water Sources: Tap water, Groundwater, River water, Industrial process water

Application Fields

-

Boiler feed water pretreatment

-

Pharmaceutical and medical water systems

Why Choose Us

-

10+ years water treatment manufacturing experience

-

Factory direct price

-

OEM & ODM available

-

Compatible with 5–10 T/H RO systems

-

Professional technical support