Single Tank Water Softener

Efficient Hardness Removal | Compact Design | Automatic Operation

The Single Tank Water Softener is designed to remove calcium and magnesium ions from hard water using sodium ion exchange technology. By reducing water hardness, it effectively prevents scale formation in pipelines, boilers, heaters, and reverse osmosis (RO) systems.

With a compact structure and automatic regeneration, this softener is ideal for applications where water demand is intermittent and continuous operation is not required during regeneration.

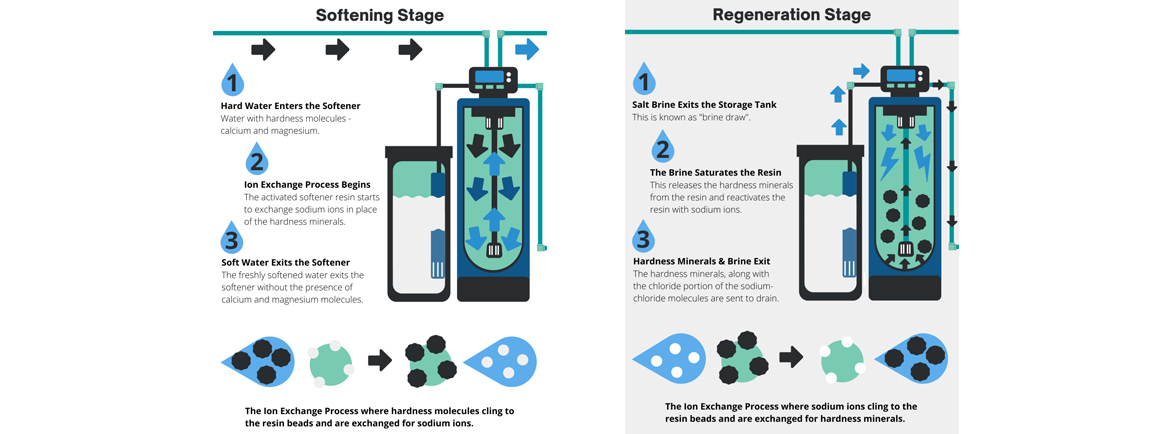

Working Principle

Hard water flows through a cation exchange resin bed, where calcium (Ca²⁺) and magnesium (Mg²⁺) ions are exchanged with sodium (Na⁺) ions. When the resin becomes saturated, the system automatically regenerates using a salt (NaCl) solution, restoring its softening capacity.

Key Advantages

-

Effective hardness removal

-

Prevents scale and equipment damage

-

Automatic regeneration, easy operation

-

Compact size, space-saving installation

-

Low operating and maintenance cost

Technical Features

-

System type: Single tank water softener

-

Capacity: Customized (0.5–50+ T/H)

-

Resin: High-quality cation exchange resin

-

Tank material: FRP / Stainless steel

-

Control mode: Time-based or flow-based control valve

-

Regeneration mode: Automatic salt regeneration

Applicable Water Sources

-

Tap water

-

Groundwater

-

Well water

Application Areas

-

Boiler and heating systems

-

Cooling water systems

-

Commercial and light industrial use

-

Hotels, residential and small factories

Why Choose Us

-

10+ years water treatment equipment manufacturing experience

-

Factory direct supply and competitive pricing

-

OEM & ODM service available

-

Stable quality and easy maintenance

-

Professional technical support