MBR membrane bioreactor

MBR classification

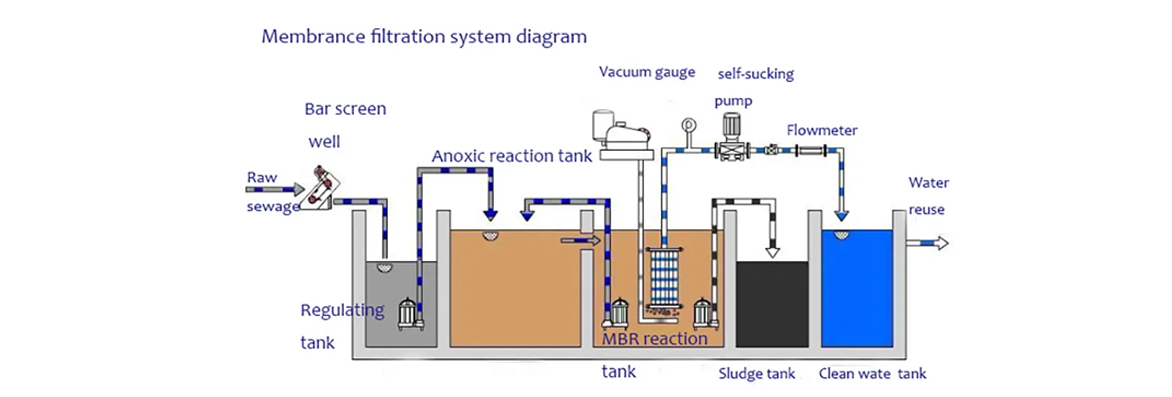

The integrated system places the membrane assembly directly within the reactor, extracting the filtrate through suction. The cross-flow required for membrane surface cleaning is generated by air agitation and is located directly below the membrane. The mixed liquid flows upward with the airflow, generating shear forces on the membrane surface to reduce membrane fouling. The integrated membrane bioreactor process is an organic combination of wastewater biological treatment technology and membrane separation technology.MBR Classification

Membrane bioreactors (MBRs) are widely used in the water treatment industry. They are categorized based on their membrane components and operating principles.

Generally speaking, MBRs can be classified as follows:

Membrane separation bioreactors: MBRs are used for solid-liquid separation in wastewater treatment.

Membrane aeration bioreactors: In MBRs, the membrane is used for gas mass transfer, typically supplying oxygen for aerobic processes. This allows for bubble-free aeration in the bioreactor, significantly improving the reactor's oxygen transfer efficiency.

Based on the placement of the membrane assembly, MBRs can be categorized as split-type and integrated.

Split-type MBRs separate the bioreactor and membrane assembly. The pressurized mixed liquor in the MBR enters the membrane assembly. Under pressure, the liquid in the mixed liquor permeates the membrane to form the system effluent, while the activated sludge is retained and returned to the bioreactor with the concentrate.