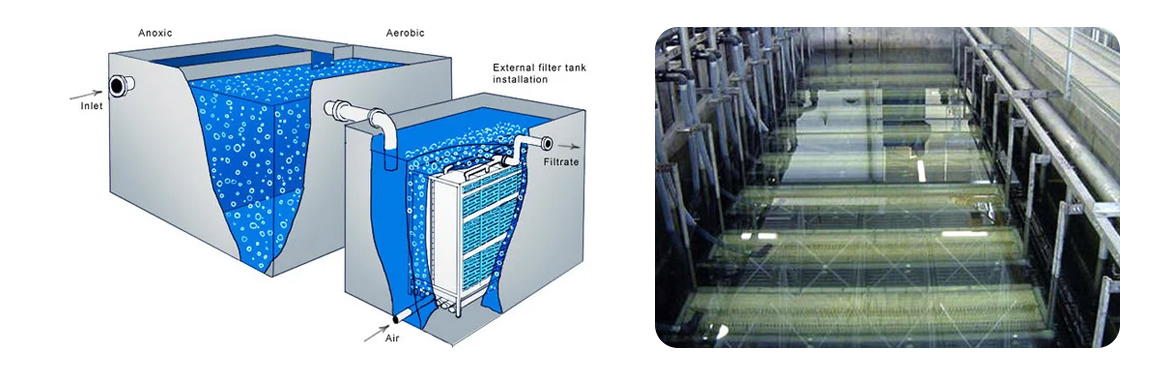

MBR membrane bioreactor

Features

1) High pollutant removal rate, strong sludge bulking resistance, stable and reliable effluent quality, and no suspended solids in the effluent;

2) The membrane bioreactor enables independent control of the reactor's sludge age (STR) and hydraulic retention time (HRT), greatly simplifying its design and operation;

3) The mechanical retention of the membrane prevents microbial loss, maintaining a high sludge concentration within the bioreactor, thereby increasing volumetric loading and reducing sludge load, and providing strong shock resistance;

4) Due to its long SRT, the bioreactor also functions as a "sludge nitrification tank," significantly reducing sludge production, resulting in low excess sludge production and low sludge treatment costs.

6) The activated sludge in the MBR aeration tank is not lost with the effluent. During operation, the activated sludge changes with the incoming organic matter concentration, reaching a dynamic equilibrium. This ensures stable effluent and resistance to shock loads.

7) The extensive hydraulic circulation results in uniform mixing of the wastewater, which in turn allows for excellent dispersion of the activated sludge, significantly increasing its specific surface area. The high dispersion of activated sludge in the MBR system further enhances water treatment efficiency. This is incomparable to the larger flocs formed by conventional biochemical water treatment technologies.

8) The membrane bioreactor is easily integrated, easily automated, and conveniently operated and managed.

9) The MBR process eliminates the need for a secondary sedimentation tank, reducing floor space.