Air Flotation Machine

High-Efficiency Solid-Liquid Separation Equipment

Product Overview

Air Flotation Machine is a solid-liquid separation device designed to remove suspended solids (SS), oils, grease, and colloidal particles from wastewater.

By generating fine microbubbles, pollutants attach to bubbles and float to the surface, where they are automatically removed, achieving efficient clarification.

It is widely used in industrial wastewater treatment, automobile painting wastewater, food processing, petrochemical, printing & dyeing, slaughterhouse, and municipal sewage pre-treatment systems.

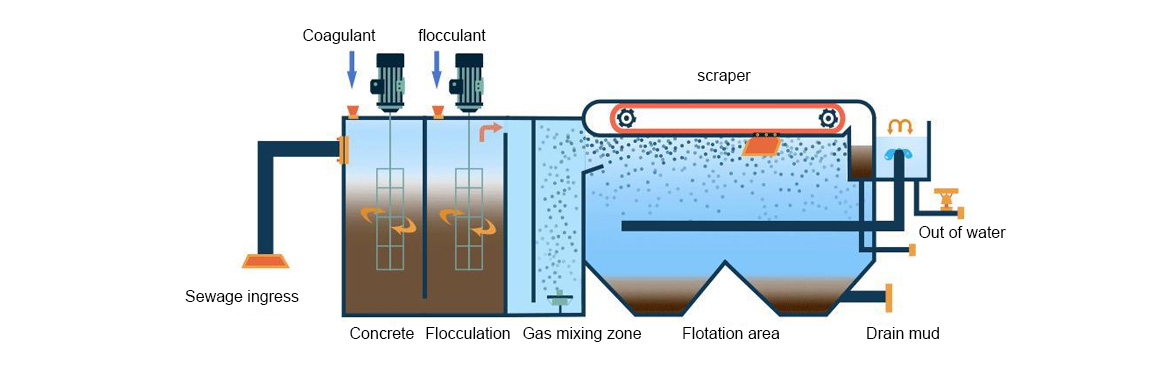

Working Principle

-

Wastewater enters the air flotation tank

-

Dissolved air is released to form microbubbles

-

Suspended solids and oils adhere to microbubbles

-

Floating flocs rise to the surface

-

Surface sludge is removed by a scraper system

-

Clarified water is discharged continuously

Application Fields

-

Automobile painting wastewater

-

Petrochemical & oily wastewater

-

Food & beverage processing wastewater

-

Slaughterhouse wastewater

-

Printing & dyeing wastewater

-

Municipal wastewater pre-treatment

Optional Configurations

-

Chemical dosing system (PAC / PAM)

-

Oil skimmer or sludge thickening system

-

PLC control cabinet

-

Skid-mounted integrated design

Reliable Air Flotation Solution

Air flotation machines provide efficient, stable, and cost-effective solid-liquid separation, making them an essential pre-treatment unit in modern wastewater treatment systems.