Hospital sewage treatment

Safe & Compliant Medical Wastewater Treatment Solution

Overview

Hospital sewage treatment refers to the treatment of wastewater generated from hospitals, clinics, and medical institutions.

This wastewater typically contains pathogenic microorganisms, viruses, bacteria, pharmaceuticals, disinfectants, and organic pollutants, posing serious health and environmental risks if discharged without proper treatment.

A dedicated hospital sewage treatment system is designed to ensure pathogen removal, stable disinfection, and compliance with local discharge standards.

Characteristics of Hospital Wastewater

-

High concentration of pathogens and viruses

-

Presence of medical chemicals and disinfectants

-

Variable flow and water quality

-

High sanitary and safety requirements

-

Strict discharge regulations

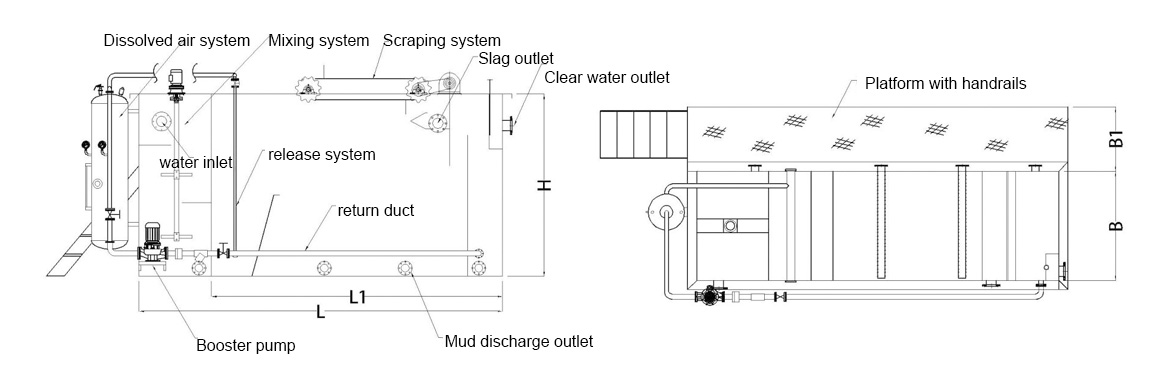

Key Treatment Units

-

Screening unit – removes large solids and debris

-

Equalization tank – stabilizes flow and water quality

-

Biological treatment system – removes COD, BOD, NH₃-N

-

Membrane filtration (MBR) – ensures high effluent quality

-

Disinfection unit – eliminates pathogenic microorganisms

Recommended Disinfection Methods

-

Chlorine dioxide generator (strong sterilization, low by-products)

-

Sodium hypochlorite generator (safe on-site chlorination)

-

UV sterilizer (chemical-free physical disinfection)

Combination disinfection can be adopted for higher safety levels.

Key Features & Advantages

-

High pathogen removal efficiency

-

Stable and reliable operation

-

Compact and integrated design

-

Automatic control & low labor cost

-

Compliant with medical wastewater discharge standards

-

Safe and environmentally friendly

Application Scope

-

General hospitals

-

Infectious disease hospitals

-

Clinics & medical centers

-

Laboratories & research institutes

-

Temporary medical facilities

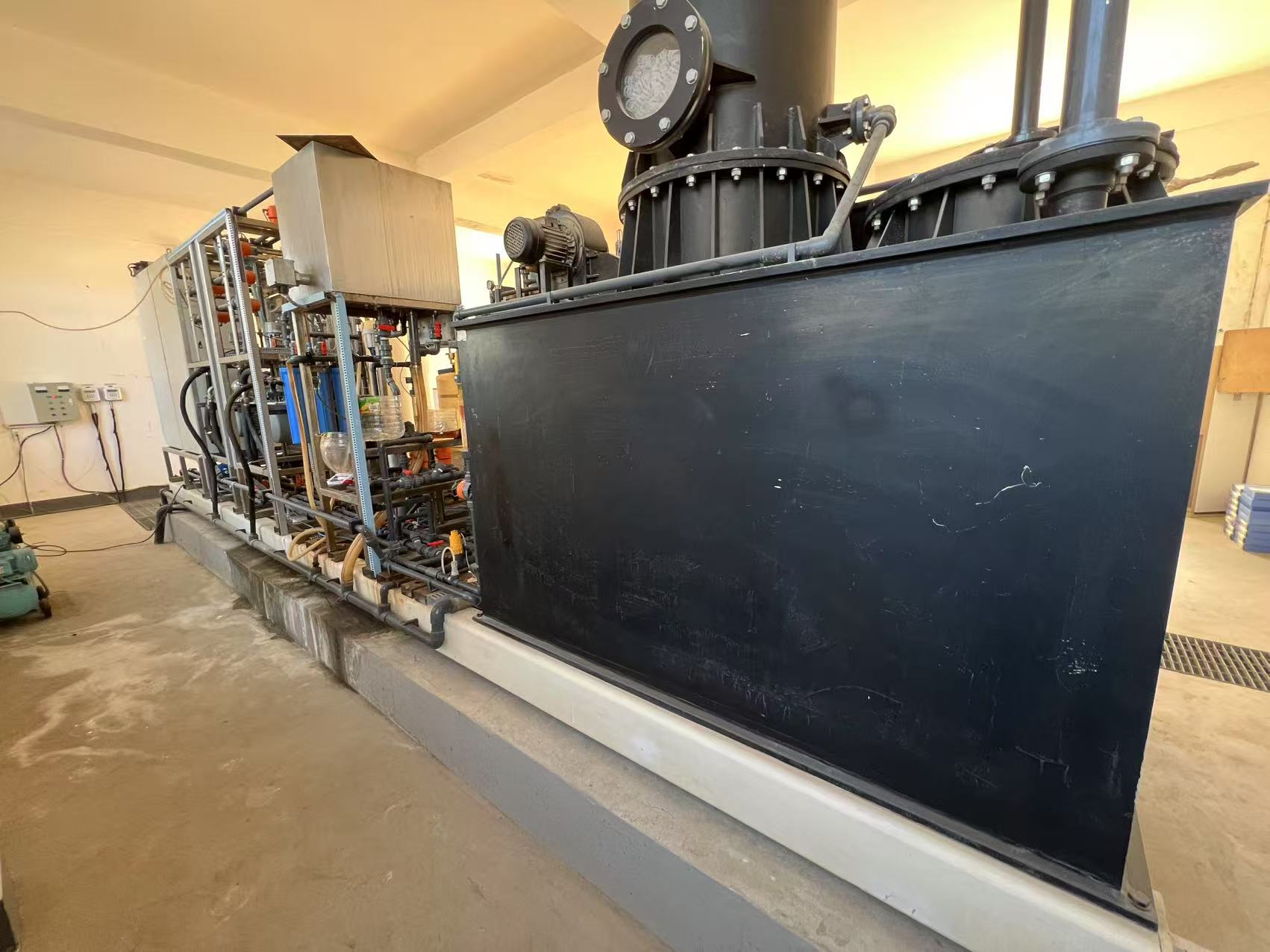

System Form

-

Integrated hospital sewage treatment equipment

-

Containerized / skid-mounted systems

-

Underground installation (optional)

-

Fully automatic PLC control

Reliable Medical Wastewater Solution

Hospital sewage treatment systems provide safe, compliant, and efficient treatment of medical wastewater, ensuring public health protection and environmental safety.