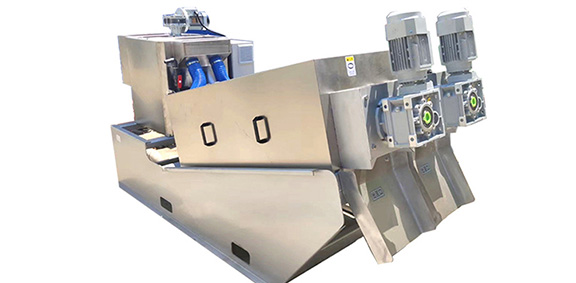

Spiral solid-liquid separator

Efficient Sludge Dewatering & Separation Solution

Product Overview

Spiral Solid-Liquid Separator is a mechanical separation device designed to efficiently separate solids from liquid in wastewater and sludge treatment processes.

Using a spiral extrusion and filtration mechanism, the separator continuously removes suspended solids, reduces sludge volume, and improves downstream treatment efficiency.

It is widely used in municipal wastewater treatment, industrial wastewater treatment, livestock farming, food processing, and sludge dewatering systems.

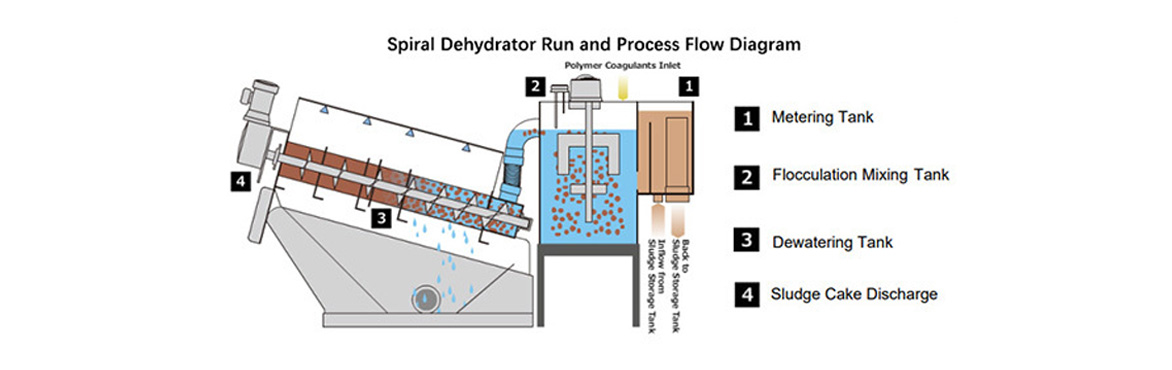

Working Principle

The spiral solid-liquid separator operates through mechanical extrusion and filtration:

-

Slurry enters the separation chamber

-

A rotating spiral screw transports the material forward

-

Liquid passes through the screen or filter gaps

-

Solids are gradually compressed and discharged from the outlet

This continuous process ensures stable separation efficiency and low energy consumption.

Key Features & Advantages

-

Continuous and automatic operation

-

High solid-liquid separation efficiency

-

Low energy consumption

-

Compact structure and small footprint

-

Low noise and vibration

-

Easy maintenance

-

Durable and corrosion-resistant materials

Application Fields

-

Industrial wastewater treatment

-

Sludge dewatering systems

-

Livestock and poultry farming

-

Food & beverage wastewater

-

Chemical and pharmaceutical wastewater

System Integration

Spiral solid-liquid separators are often used together with:

-

Flocculation dosing systems

-

Sludge thickening tanks

-

Screw conveyors

-

Sludge drying or disposal systems

Reliable Separation Equipment

The spiral solid-liquid separator provides stable performance, reduced sludge volume, and lower operating costs, making it an efficient and economical solution for solid-liquid separation.