Inclined screen solid-liquid separator

Working Principle

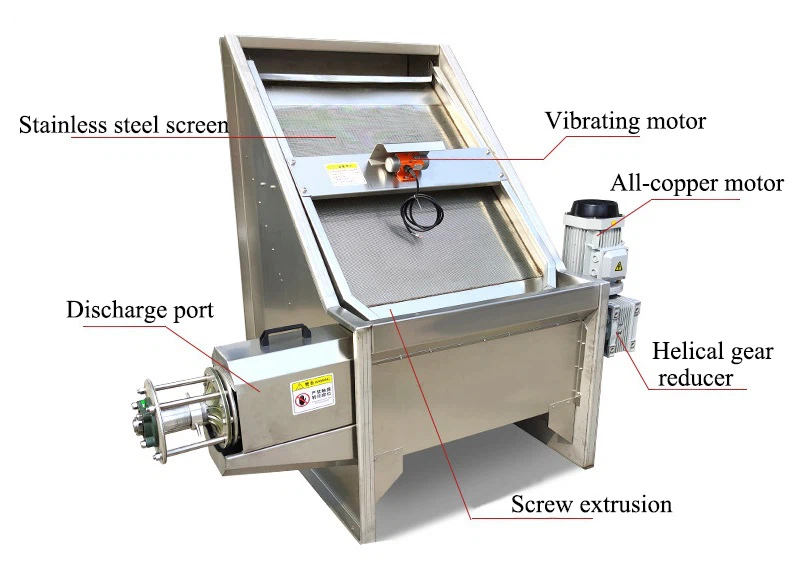

Structural Composition

It primarily consists of a spiral auger, a cylindrical filter, an inclined screen, a reduction motor, and a vibrating motor. Some units are also equipped with an electronic control system and a cutting pump to enable automated operation and material conveying.

Equipment Features

High-Efficiency Processing: Processing capacity reaches 10-60 cubic meters per hour. After separation, the liquid solids content is less than 1%, and the solids moisture content can be reduced to 30%-60%.

Low Energy Consumption: Utilizing the gravity of the water flow, the machine operates without energy consumption. The low power consumption of the press allows for high water throughput per unit, resulting in low operating costs.

Durability: The entire machine is typically constructed of 304 stainless steel, which offers high strength, deformation resistance, corrosion resistance, and a long service life.

Easy Operation: The external screen design facilitates cleaning, and the electronic control system supports automated operation, enabling unattended operation and facilitating daily management and maintenance.

Application Areas

Livestock and Poultry Farming: Used for dehydrating livestock and poultry manure such as pig, chicken, and cow manure, as well as separating biogas residue in biogas projects.

Food and Agricultural Processing: Used for solid-liquid separation of food processing byproducts such as distiller's grains, bean dregs, starch residue, and soy sauce residue, as well as crop residues such as straw and traditional Chinese medicine residue.

Industrial Wastewater Treatment: Suitable for industries such as papermaking, slaughtering, printing and dyeing, and chemical processing, removing suspended solids, sediments, and colloids from wastewater, reducing the burden on subsequent treatment.