Horizontal Flotation Machine

Efficient Solid-Liquid Separation Equipment

Product Overview

Horizontal Flotation Machine is a high-efficiency solid-liquid separation device designed for oil-water separation, suspended solids removal, and wastewater pre-treatment.

By generating a large number of microbubbles, the system allows suspended solids, oils, and grease to attach to bubbles and float to the water surface, where they are automatically removed.

It is widely used in industrial wastewater treatment, automobile painting wastewater, food processing, petrochemical, slaughterhouse, and municipal sewage pre-treatment systems.

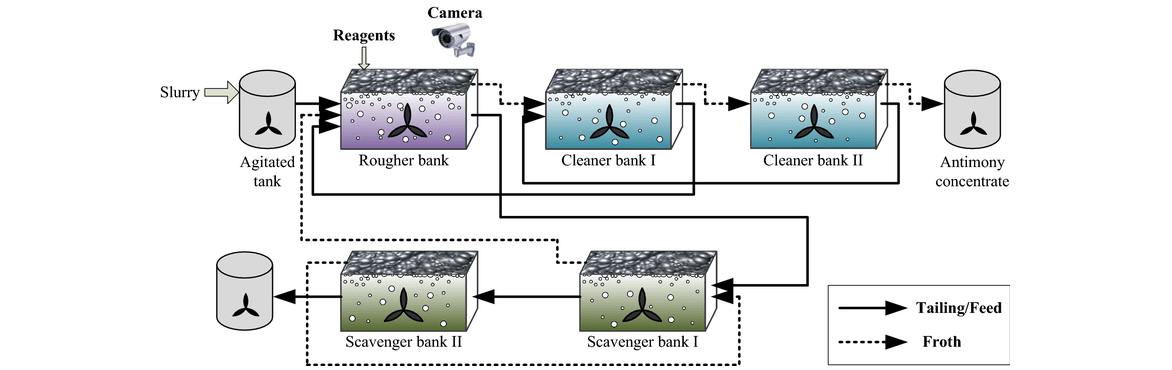

Working Principle

-

Wastewater enters the horizontal flotation tank

-

Microbubbles are generated by the air dissolution system

-

Suspended solids and oils adhere to microbubbles

-

Flocs float to the surface forming a scum layer

-

Scraper system removes floated sludge

-

Clarified water flows out continuously

Key Features & Advantages

-

High solid-liquid separation efficiency

-

Compact horizontal structure

-

Stable and continuous operation

-

Low energy consumption

-

Automatic sludge discharge

-

Easy installation & maintenance

-

Suitable for high oil and SS wastewater

Application Fields

-

Automobile painting wastewater

-

Petrochemical & oilfield wastewater

-

Food & beverage processing

-

Slaughterhouse wastewater

-

Printing & dyeing wastewater

-

Municipal wastewater pre-treatment

Optional Configurations

-

Chemical dosing system (PAC / PAM)

-

Sludge thickening tank

-

PLC automatic control cabinet

-

Skid-mounted integrated design

Reliable Flotation Treatment Solution

Horizontal flotation machines provide stable, efficient, and cost-effective solid-liquid separation, making them an ideal pre-treatment solution for complex industrial wastewater systems.