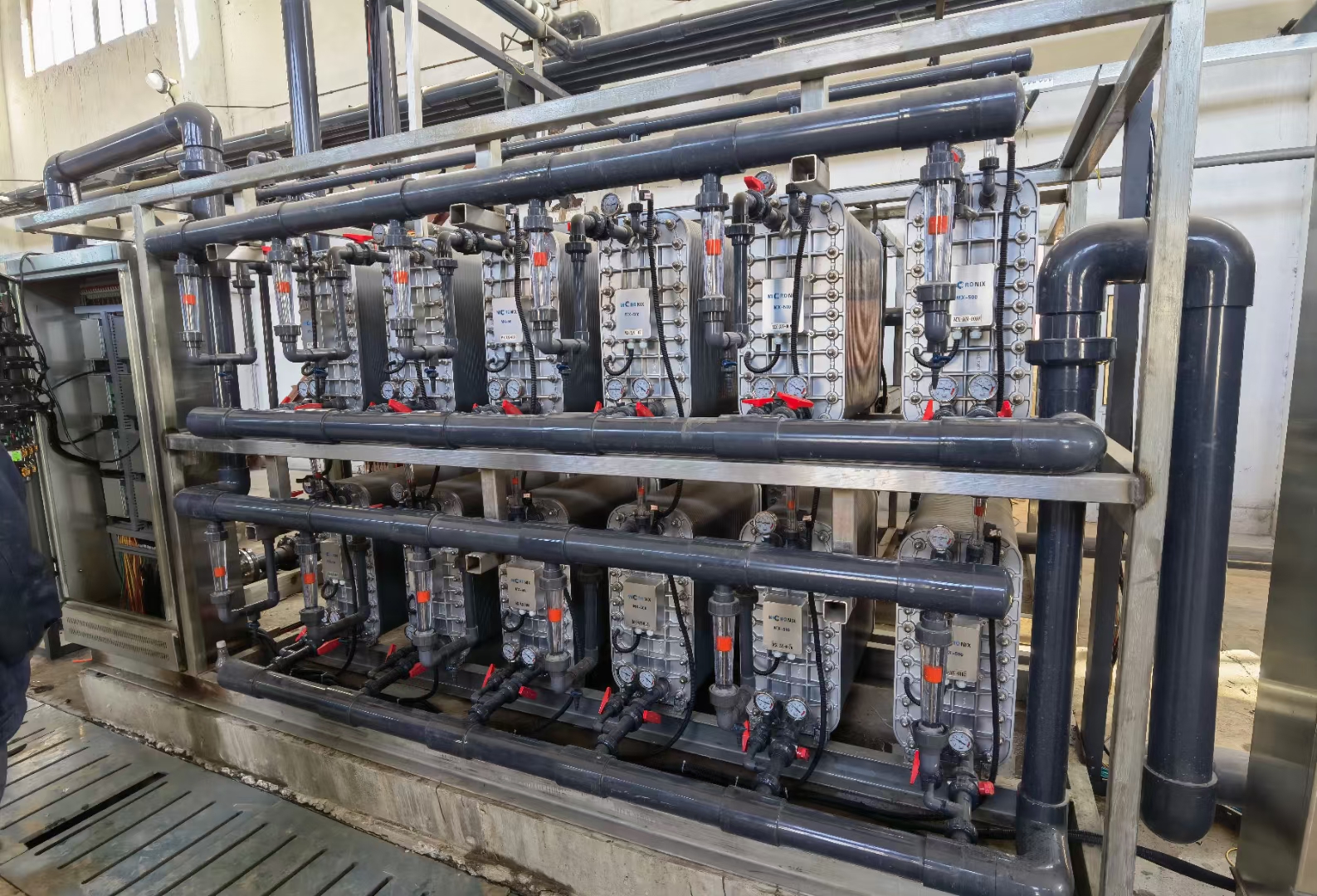

Industrial EDI ultrapure water equipment

Process Flow

Raw Water → Pretreatment → RO (Single / Double Stage) → EDI Module → UV Sterilization → Polishing Filter → Ultrapure Water Storage

1. Sedimentation: Utilizing natural sedimentation or chemical softening, sedimentation is performed to remove impurities from the water, resulting in sedimentation of silt, large suspended solids, or hardness.

2. Coagulation and Clarification: Coagulants are used to cause solid particles in the water to adhere to each other, changing their size, shape, and density, thereby separating them from the water.

3. Filtration: This is a widely used pretreatment technology. Combined with resin materials, impurities are trapped by the filter media, resulting in clarified water quality.

Using scientific and rational methods to pretreat raw water ensures the continuous and stable operation of the EDI water purification system. The application of pretreatment technology lays the foundation for pure water production.

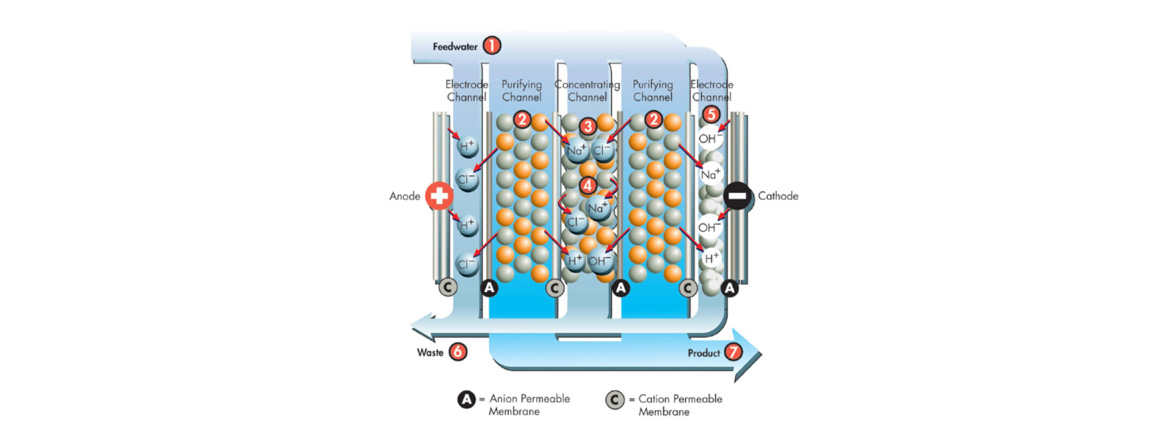

EDI ultrapure water treatment

2. Continuous and simple operation: In a mixed bed, the operation process becomes complicated due to each regeneration and fluctuations in water quality. However, EDI's water production process is stable and continuous, with consistent water quality. There are no complex operating procedures, greatly simplifying operation.

3. Reduced installation requirements: Compared with a mixed bed of similar water capacity, the EDI system is smaller in size. Its modular design allows for flexible configuration based on site height and layout. This modular design makes the EDI system easy to maintain during production.

Why Choose Us

-

10+ years ultrapure water system manufacturing experience

-

RO + EDI integrated solution provider

-

OEM & ODM service available

-

Stable performance and easy maintenance

-

Technical support and system customization