MBR membrane bioreactor

Advanced Wastewater Treatment Technology

Product Overview

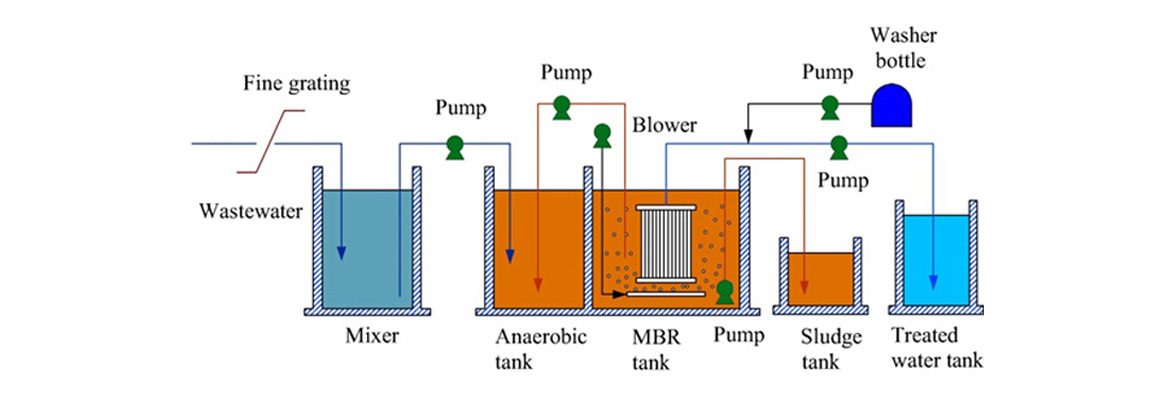

MBR (Membrane Bioreactor) is an advanced wastewater treatment system that combines biological treatment with membrane filtration technology.

By replacing the traditional secondary sedimentation tank with membrane separation, MBR systems achieve high-quality effluent, stable operation, and compact system design.

MBR membrane bioreactors are widely used in municipal sewage treatment, hospital wastewater, industrial wastewater, water reuse, and decentralized sewage treatment projects.

Working Principle

-

Wastewater enters the biological reaction tank

-

Microorganisms degrade organic pollutants (COD, BOD, NH₃-N)

-

MBR membranes separate solids and liquids

-

Suspended solids and bacteria are completely retained

-

High-quality treated water is discharged or reused

Key Features & Advantages

-

Excellent effluent quality

-

High sludge concentration (MLSS)

-

Small footprint

-

Strong resistance to shock loads

-

Complete retention of bacteria and pathogens

-

Suitable for water reuse applications

-

Fully automatic operation

Application Fields

-

Municipal sewage treatment

-

Hospital & medical wastewater

-

Industrial wastewater treatment

-

Rural & decentralized sewage systems

-

Reclaimed water & reuse projects

Optional Configurations

-

Integrated MBR sewage treatment equipment

-

Online TMP & flux monitoring

-

Automatic membrane cleaning (CIP)

-

UV / Chlorine dioxide disinfection

Advanced Sewage Treatment Solution

MBR membrane bioreactors provide stable, efficient, and high-standard wastewater treatment, making them an ideal solution for projects requiring strict discharge or reuse standards.