Small Seawater Desalination Equipment

Product Overview

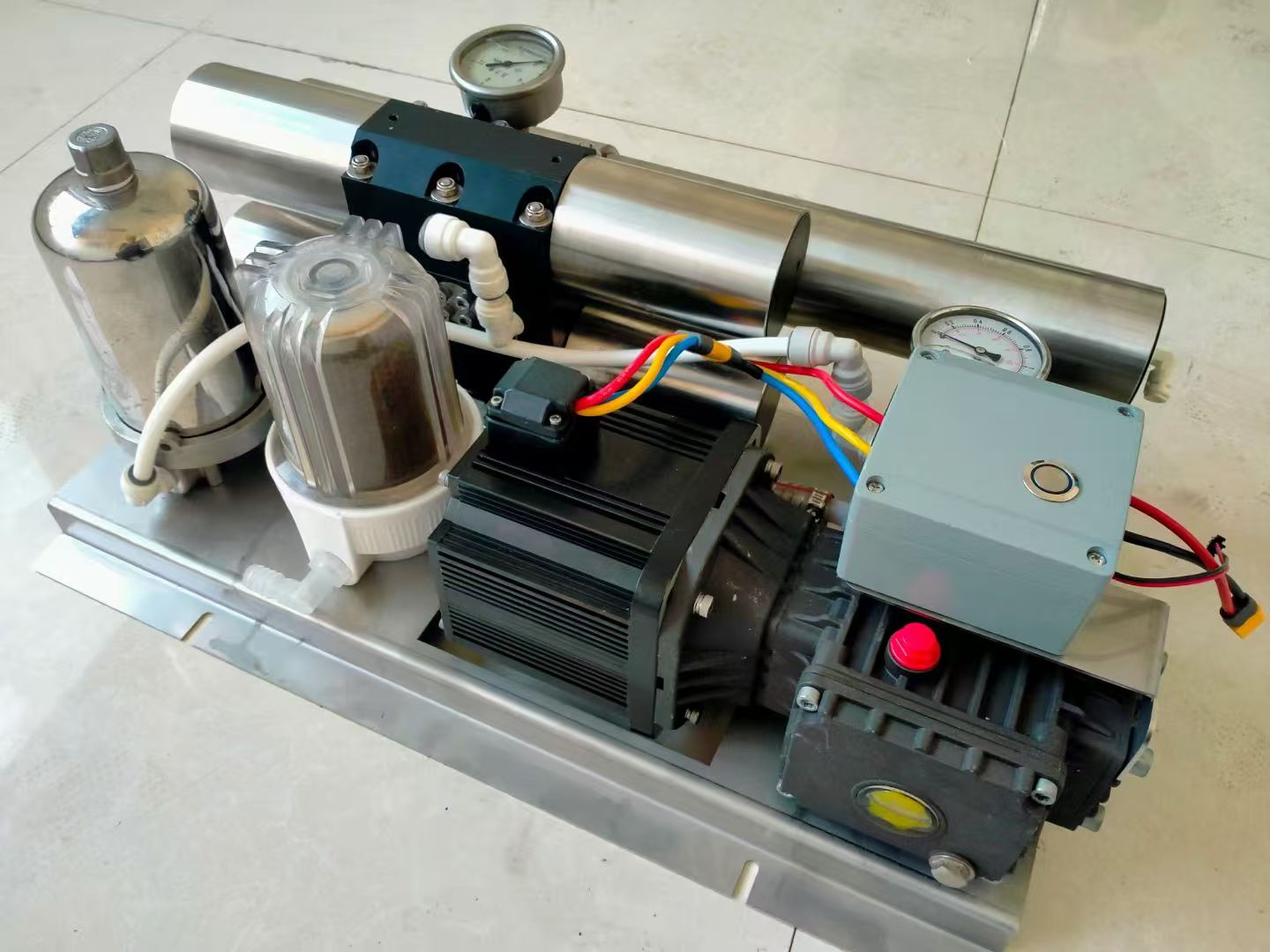

Small Seawater Desalination Equipment is a compact reverse osmosis system designed to convert seawater into clean and usable fresh water for small-scale applications.

Using advanced seawater RO membrane technology, the system efficiently removes dissolved salts, microorganisms, and impurities, providing a stable freshwater supply in areas with limited resources.

This equipment is ideal for islands, coastal villages, ships, resorts, offshore platforms, and emergency water supply.

Working Principle

The system adopts a pretreatment + seawater reverse osmosis process:

-

Pretreatment unit removes suspended solids, turbidity, and organic matter

-

High-pressure pump provides the required pressure to overcome seawater osmotic pressure

-

Seawater RO membranes separate fresh water from salt and contaminants

-

Post-treatment (optional) improves taste and mineral balance

This process ensures high desalination efficiency and reliable operation.

Key Features & Advantages

-

Compact and space-saving design

-

High salt rejection rate (≥99.7%)

-

Low energy consumption

-

Easy installation and operation

-

Automatic control system

-

Corrosion-resistant materials

-

Low maintenance cost

Application Areas

-

Small islands & coastal areas

-

Ships & yachts

-

Resorts & hotels

-

Offshore platforms

-

Emergency drinking water supply

-

Remote communities

System Configuration Options

-

Capacity: 0.25–20 m³/day

-

RO membrane brands: DuPont / Toray / Vontron

-

Power supply: 220V / 380V / Diesel generator

-

Skid material: Carbon steel / SS304 / SS316

-

Optional units: Energy recovery device, UV sterilizer, remineralization filter