Compact Seawater Desalination System

Space-Saving & Efficient Freshwater Solution

Product Overview

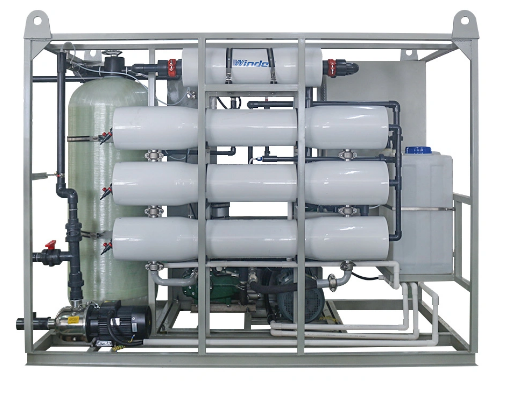

The Compact Seawater Desalination System is a fully integrated reverse osmosis solution designed to convert seawater into high-quality fresh water within a small footprint.

With a modular and compact structure, the system is ideal for locations where space is limited while maintaining high desalination efficiency and stable performance.

It is widely used for ships, offshore platforms, islands, resorts, coastal communities, and emergency water supply.

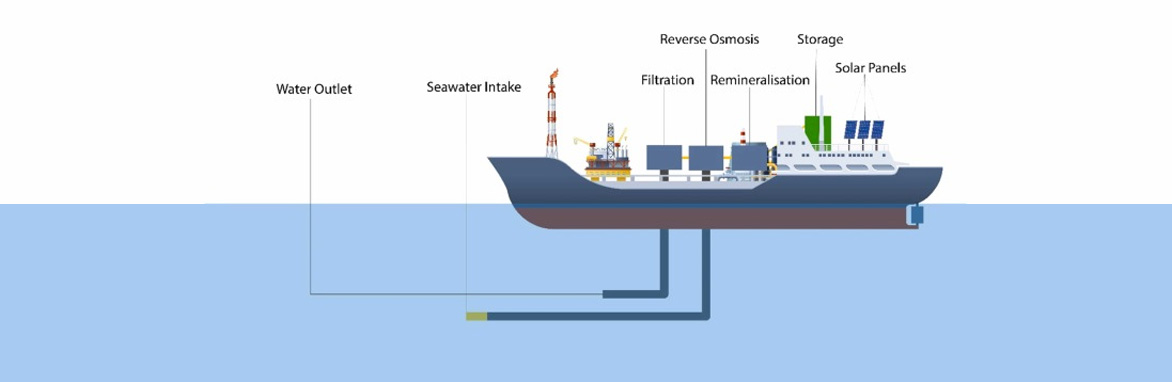

Working Principle

The system combines pretreatment and seawater reverse osmosis into a compact skid-mounted design:

-

Pretreatment removes suspended solids, turbidity, and organic matter

-

A high-pressure pump drives seawater through RO membranes

-

Seawater RO membranes separate salt and contaminants from fresh water

-

Optional post-treatment improves water taste and mineral balance

This process ensures reliable desalination and continuous freshwater output.

Key Features & Advantages

-

Ultra-compact and integrated design

-

High salt rejection rate (≥99.7%)

-

Low energy consumption

-

Plug-and-play installation

-

Automatic control system

-

Corrosion-resistant materials

-

Low maintenance requirement

Application Areas

-

Ships & yachts

-

Offshore platforms

-

Small islands

-

Resorts & hotels

-

Emergency desalination systems

-

Remote coastal communities

System Configuration Options

-

Capacity: 0.5–50 m³/day

-

RO membrane brands: DuPont / Toray / Hydranautics

-

Power supply: 220V / 380V / Diesel generator

-

Frame material: SS304 / SS316

-

Optional units: Energy recovery device, UV sterilizer, remineralization filter