Large Water Softening Equipment

Working Principle

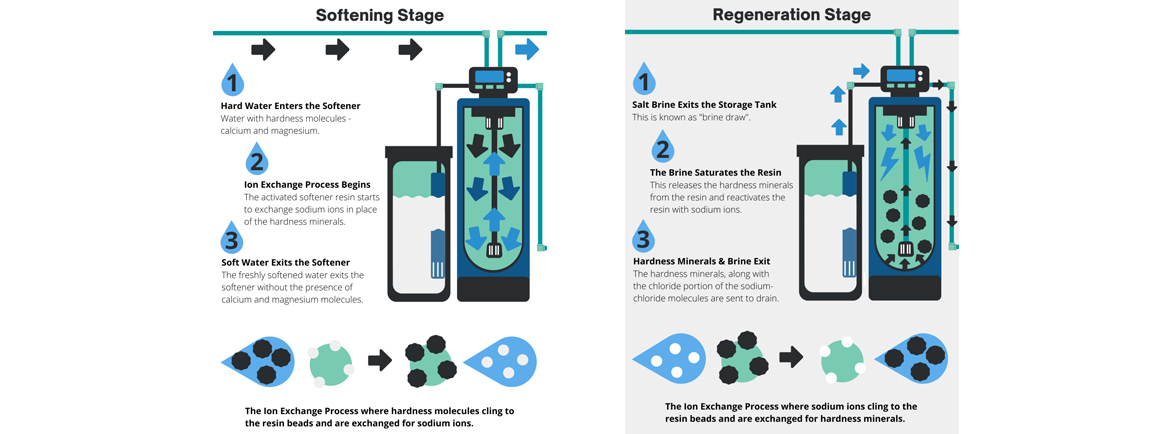

1. Ion Exchange: Sodium ions in the resin exchange with calcium and magnesium ions in the water to produce softened water. Once the resin is saturated, it must be regenerated with highly concentrated brine to restore its exchange capacity.

2. Membrane Separation: Physical methods such as reverse osmosis membranes separate solutes and solvents, further reducing hardness.

Application Scenarios

1. Industrial: Applications requiring scale prevention, such as boiler water replenishment, air conditioning systems, and chemical and pharmaceutical industries.

2. Consumer: Extending the lifespan of appliances like water heaters and washing machines while reducing scale buildup.

3. Food/Beverage: Eliminating the impact of hard water on product quality, such as preventing mineral precipitation in beverage production.

Equipment Features

Automated Control: Some equipment is equipped with hydraulic valves and computer controllers for process automation.

1. Low Energy Consumption: Power consumption is approximately 20W/day, and the operating temperature range is 2-45°C.

2. Regeneration Method: Cocurrent or countercurrent regeneration is available, with countercurrent regeneration offering higher efficiency and lower salt consumption.